Wednesday February 19, 2014

Fixing Chuck's Keyboard Part 6

Success at last!

When we left our hero yesterday he was thinking about a good night's sleep and how he would solve the mystery of the broken coil wire. (Hang on, I have to get out of third-person mode). So I thought about it until sweet slumber overtook me, and came up with a plan. I couldn't start first thing today due to ferrying Logan and Sanaz to the airport but as soon as Bonne and I got home I got busy.

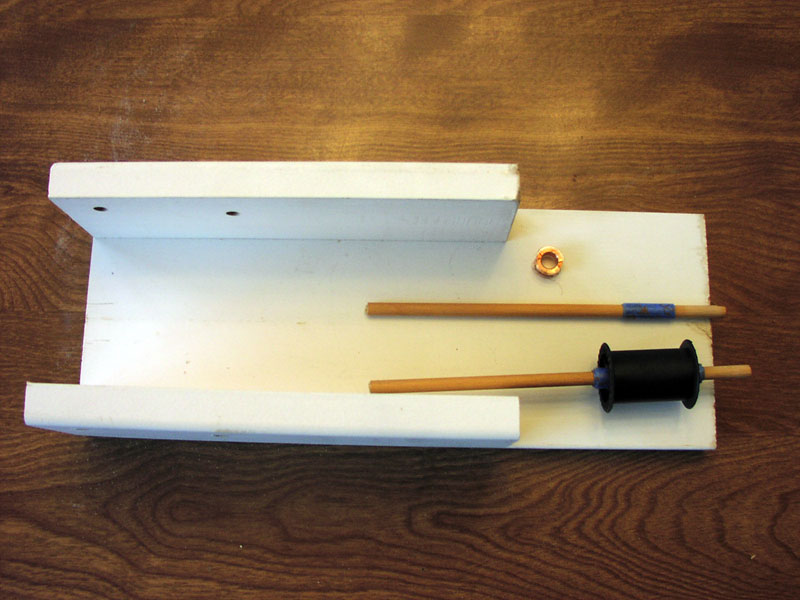

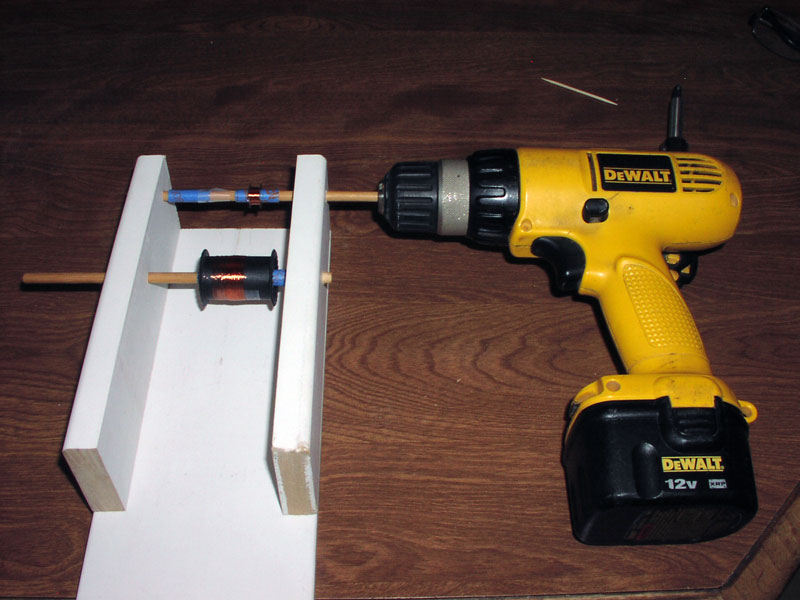

The first thing was to make a jig to hold everything in place whilst I worked:

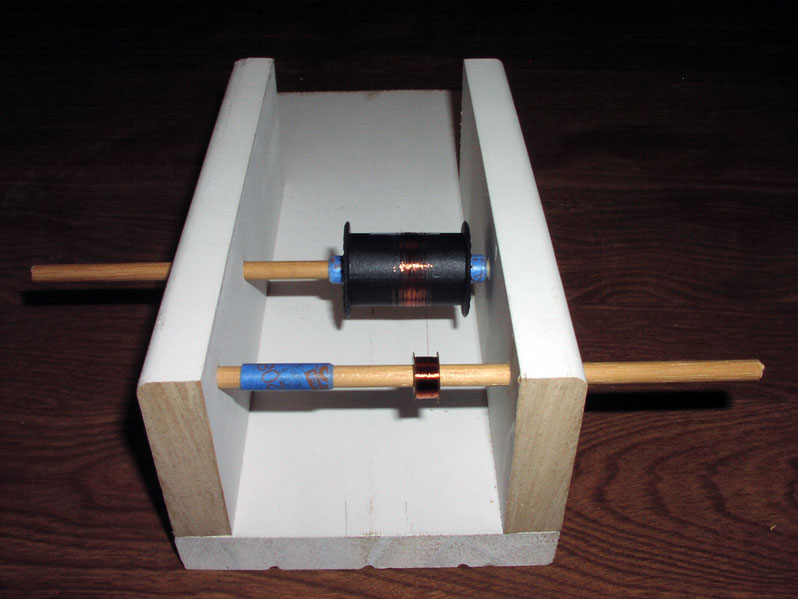

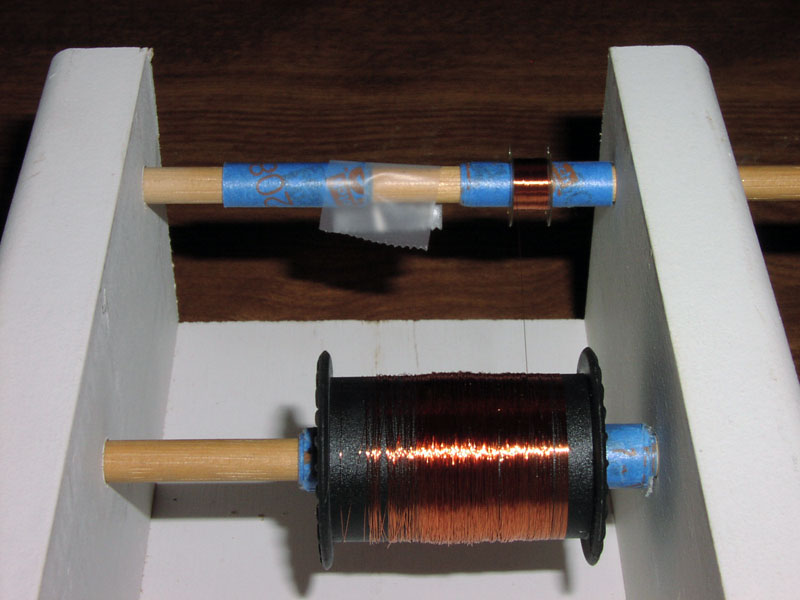

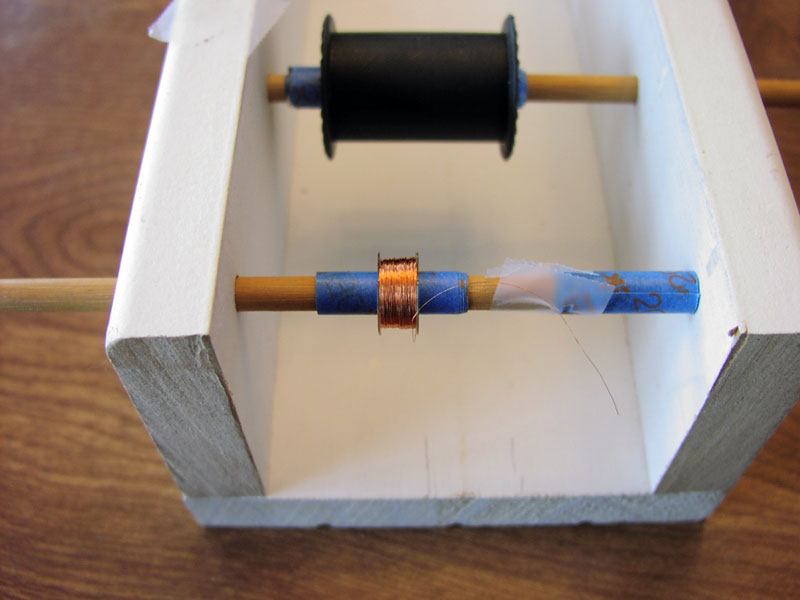

Scraps of wood and leftover dowels with a bit of tape so things would fit snugly. The dowels needed to spin in their holes but not too freely, as I needed some tension while unwinding and winding the coil.

I was really worried about this part of the operation because I needed to make sure I didn't break the wire. So the coil bobbin was off the tape and spinning freely while I wound it onto the thread spool. Since the spool was so much larger than the bobbin I turned the dowel by hand.With the wire almost off the bobbin I'm getting ready to tape it to the spool.

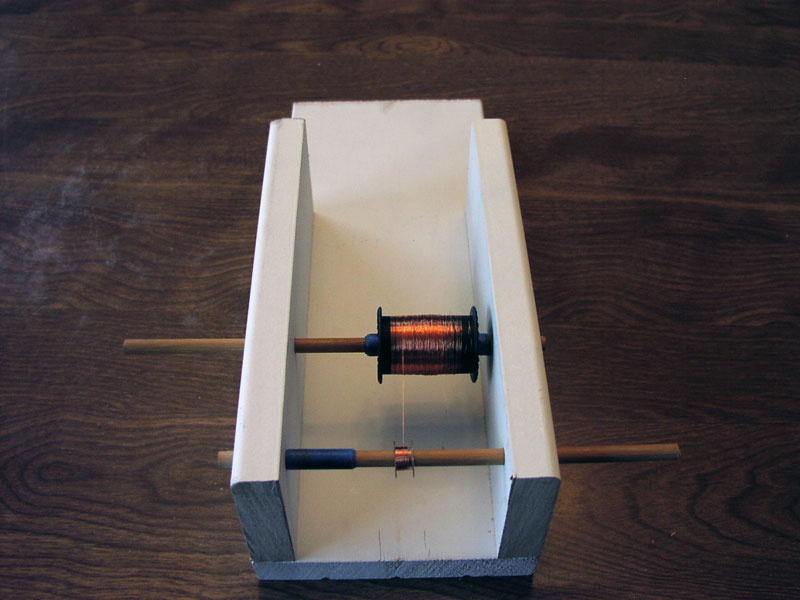

Once all the wire was off I rearranged the take-up dowel for the bobbin. I had to tape the wire to the dowel and start winding the bobbin. There was a little too much tension on the spool dowel so I soaped it up to get it to spin a little easier, with success.

Since the tension seemed OK and I had between 400 and 500 turns of wire to do I thought I'd pep things up a bit and brought out the drill. It actually worked quite well and probably cut 20 minutes off the project.

Everything went smoothly and my fears of breaking the wire were unfounded. I even managed to wind the coil fairly evenly.

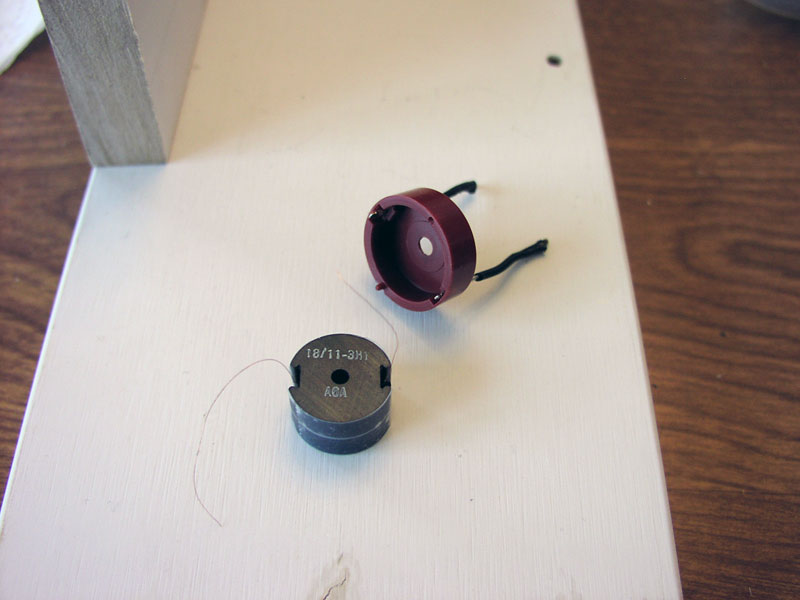

So now I had the coil wound but my work wasn't done yet. One of the things I noticed when I took the coil off the board was that it rattled a bit. The coil bobbin sits inside this black housing which in turn sits inside the brown outer case. The bobbin had some play inside the black case and I believe that the reason the wire broke in the first place was that things were moving around inside there. I padded things a little with bits of tissue and then taped the two halves if the inner housing together.

Now I had to solder the coil wires to the outer case. There was barely any room to work and I ended up using a pair of forceps and a toothpick to wrap the wire around the terminals so I could solder. Remember, that wire is just a little thicker than human hair.

When I finished soldering I gently set the inner housing in the outer case, put the bottom half on and screwed it together. I was really stressing the next part, but I got out the multimeter, set it to ohms and checked for continuity. YES, we have continuity, 6K ohms and I'm a happy guy. I grabbed the coi and my keys and headed to RaElCo to see if they could measure it and possibly produce a spare. It measured 250 millihenrys but they didn't have one, which was OK, I had a working coil. All that was left was to get home, install it and see if it worked.

I wasn't disappointed:

| < 02/18/14 |